Rubber Stamps and Industrial Inks

April 15, 2024

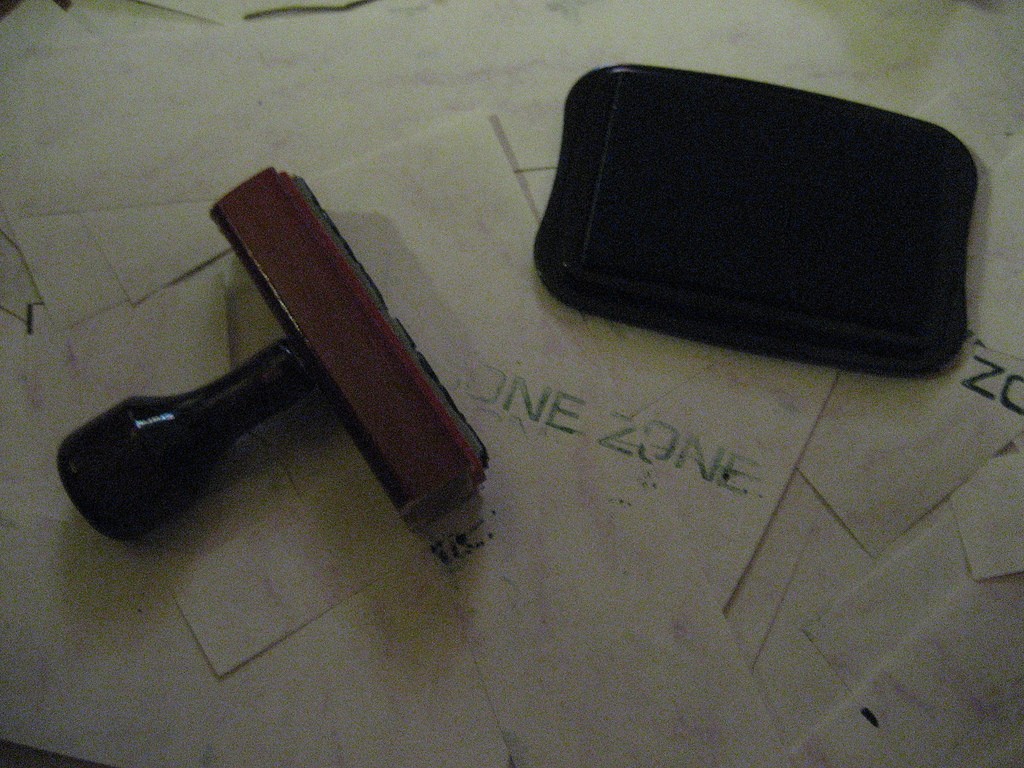

Industrial inks are used for coding, marking, and identification. Some of these applications require the use of rubber stamps to imprint on products. Rubber stamps encompass those used for crafting, scrapbooking, self-inking address stamps, office stamps, and pre-inked industrial stamps that are used in manufacturing. While the kind of stamp you use is crucial to the application, the ink is just as important to the stamping.

When you think of industrial stamps, tools, and inks, you view them as things only used for industrial purposes. While that may be true for the most part, there are applications where industrial rubber stamps and inks can be used for other purposes. Here are a few ways you can benefit from using the features industrial inks provide.

The very nature of industrial ink is its formulation that can adhere to a variety of surfaces and can endure higher intensity environments. The average rubber stamps are designed to stamp on porous surfaces like paper or scrapbook paper, however, industrial inks can make lasting marks on non-porous surfaces like metals, plastics, glass, ceramics, glossy paper, food packaging, laminated paper, and other non-porous materials.

Because industrial inks can be effectively used on non-porous materials, it opens a multitude of opportunities for stamping on more surfaces. For instance, you can use industrial inks to mark inside electrical machinery. A carpenter or machinist can also brand their tools with their business name or name to personalize or prevent theft. Industrial ink is heat resistant and is capable of enduring excessive weather conditions. Imagine how that could help you with your business if you use glossy catalogs without having to handwrite your name and business address on every catalog. It will save you time and prevent smudging.

Scrapbooking hobbyists and enthusiasts can benefit from using industrial inks for stamping on various surfaces as well. Most often, these crafty artists work with pigment ink pads that are water-based for porous paper products. Coated, laminated, glossy, and photo paper is less porous, therefore these crafters can enjoy a whole new way of producing arts and crafts for themselves and for sale. Photographers can use industrial inks on coated paper or calendar-style paper to create text, signatures, or other stamped images to their images and art. For instance, they can brand the back of a picture they take to preserve and protect their brand. It dries fast and doesn’t easily rub off or ruin a photo.

Before industrial inks were available to photographers and photographic studios, it took time to get the ink to dry, whereas today, it takes only 10 to 15 seconds, making wait times faster, which results in better business practices. This way, photographers can stamp their copyright or brand their photos with smudge-proof, long-lasting inks. It’s ideal for photographers that mail their images to clients.

Industrial inks are commonly used in the food industry on packaging. Now, small businesses that make and sell baked goods can do the same. They can use food safe ink that won’t smudge on just about any surface used for the labels. What a difference industrial inks can make even in small business or personal applications.

Article submitted by Erryn Deane

Erryn is the digital business manager for The Needham Group of companies, including Needham Ink – with a wealth of knowledge in specialty inks, laser marking systems, amongst many other things, he has decades of experience in online development, business analysis and management. In his spare time, he likes to find out how things work and looks to improve them, from vehicles to electronics or even musical instruments.

Darin is a wonderful person. He is very nice and always willing to help out! He loves his job because it lets him share interesting things with people who want to know about new developments in the world of technology.