Why Is Cable Assembly Manufacturing So Essential in Modern Industries?

July 23, 2024

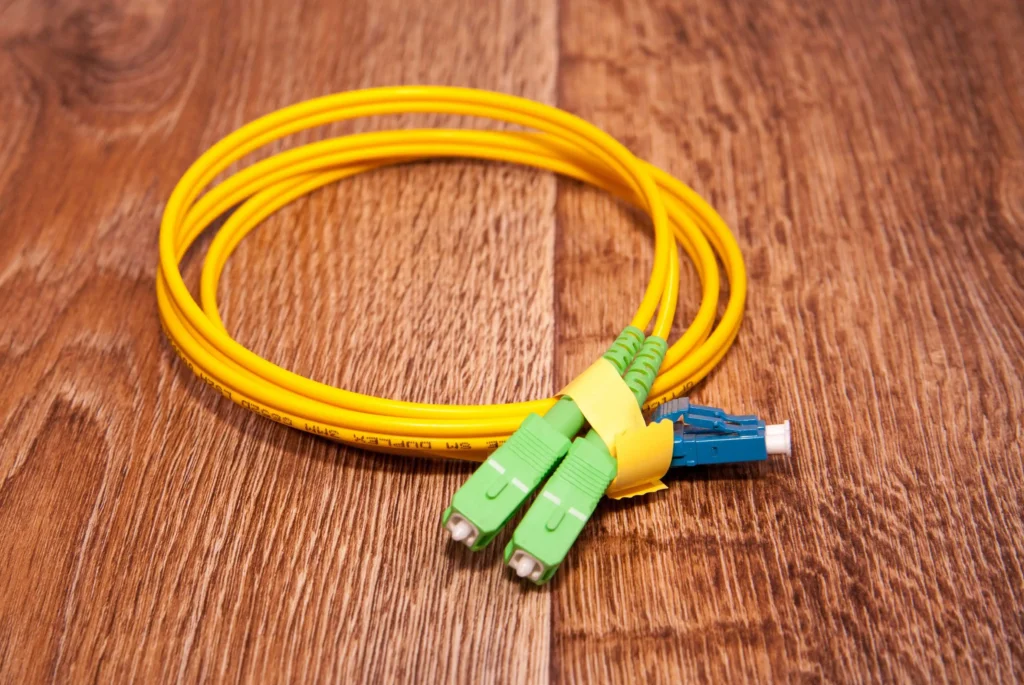

Cable assembly manufacturing is a vital component of various industries, providing customized solutions for complex electrical and electronic systems. But what exactly makes this manufacturing process so essential in modern industries?

Content

The Importance of Customization

In today’s technologically advanced world, off-the-shelf cables often don’t meet the specific needs of various applications. This is where cable assembly manufacturing comes into play. Custom cable assemblies are designed to meet unique specifications, ensuring optimal performance, reliability, and efficiency. They can be tailored in terms of length, connectors, and shielding to match the exact requirements of the equipment they will be used with.

Enhancing Efficiency and Performance

Custom cable assemblies are engineered to reduce signal interference and improve electrical performance. By incorporating high-quality materials and precise manufacturing techniques, these assemblies ensure that devices operate at their peak efficiency. This is crucial in industries such as aerospace, automotive, and telecommunications, where even minor disruptions can lead to significant issues.

Durability and Reliability

One of the key benefits of cable assembly manufacturing is the durability and reliability it offers. Custom cables are often subjected to rigorous testing to ensure they can withstand harsh environments, mechanical stress, and extreme temperatures. This is particularly important in sectors like military and defense, where equipment must operate flawlessly under demanding conditions.

Simplifying Complex Systems

In complex systems, such as industrial machinery or medical devices, having a single, unified cable assembly can significantly simplify the installation and maintenance process. It reduces the need for multiple connectors and cables, minimizing the risk of errors and enhancing overall system reliability. This simplification not only saves time but also reduces costs associated with maintenance and downtime.

Compliance with Industry Standards

Custom cable assemblies are often designed to comply with specific industry standards and certifications. This compliance ensures that the cables meet stringent safety and performance criteria, providing peace of mind to manufacturers and end-users alike. Whether it’s for medical devices that require sterilizable cables or automotive applications that need high-temperature tolerance, custom cable assemblies can be manufactured to meet these exacting standards.

Conclusion

The role of cable assembly manufacturing in modern industries cannot be overstated. From ensuring optimal performance and reliability to simplifying complex systems and adhering to industry standards, custom cable assemblies are essential for the seamless operation of various applications. As technology continues to advance, the demand for specialized cable solutions will only grow, further highlighting the importance of this critical manufacturing process.

Darin is a wonderful person. He is very nice and always willing to help out! He loves his job because it lets him share interesting things with people who want to know about new developments in the world of technology.